|

I've spent the last week designing a small pickup winder for my workshop. This is my fourth design. I've learned a lot about mechanisms, Arduino, sensors and fabrication through making these machines, and to date haven't made nearly as many pickups as I would like due to the winding machines not working as they were supposed to. All in all, winding pickups is fiddly and frustrating, but it's so satisfying when after all the hard graft you have something that works. The first image shows an electric drill rigged up to a portable drill press, with a tachometer made from a hacked pedometer and reed switch, and a bolt for adjusting the speed of the motor. The drill was old and the motor speed fluctuated so much that the magnet wire kept breaking.

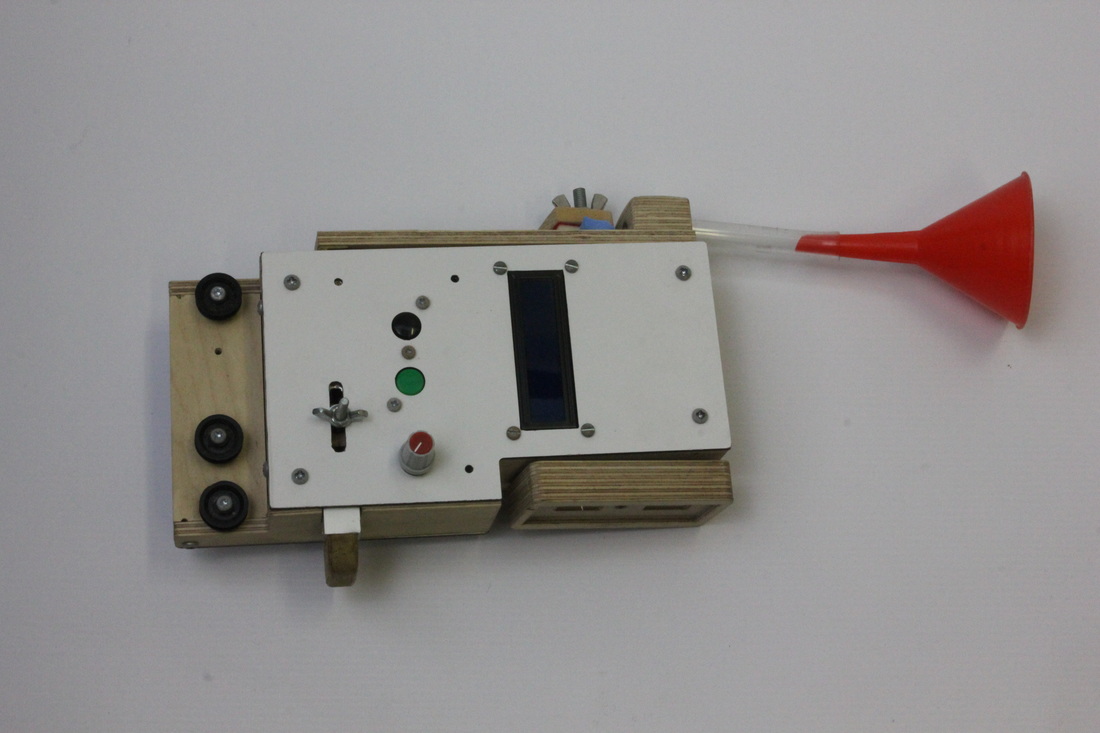

The second image shows my "deluxe" attempt. I wanted to bring some new skills to the fore in developing this, namely ability to use CAD, and hence get parts laser cut, and the use of Arduino. Partly based on the plans by Jason Lollar with a nicer look and some high tech bits, this build was plagued with problems. Using a universal AC sewing machine motor to drive the shaft, a stepper motor hacked from a scanner for the traversal (to feed the wire onto the pickup bobbin from side to side so if doesn't all bunch up in one position), an LCD for RPM and wind count, a numeric keypad and an Arduino Mega doing the number crunching. My plan with this was a fully automated machine that would count turns, calculate resistance, have variable "scatter" patterns and turn itself off when the desired count was reached. However, while I got a lot of the separate functions working, I had major issues with noise from the sewing machine motor, and couldn't get the tachometer working (based on an IR beam break setup). The tachometer is essential as without knowing how many turns of wire have gone onto the bobbin, none of the other functions are any use. So after coming very close to getting it to work I decided I could do better and scrapped it. Version 3 from 2014 was made with the benefit of having a CNC router. I never got around to making a proper PCB for this as I was swamped with other projects last year, but I did wind about 30 pickups on it successfully. In this design I used a 24V pancake motor with a built in encoder which made counting turns with an Arduino trivial. A servo motor was to take care of traversing the wire onto the bobbin, feeding the wire through the ball end of a guitar string which the servo moved up and down. I went for a non-traditional orientation of the main motor, but soon realised why this wasn't used in other design. The traversal distribution wasn't even- gravity tends to favour the bottom rather than the top! Anyway, due to this flaw I decided to scrap the machine and start again. The new machine, which is based around a 200RPM geared 12v DC motor, is greatly simplified. I wanted something small and portable with minimal controls - speed pot, start/stop button, and reset button. There is a manual traverse with a mechanism for limiting the travel to accommodate different bobbin widths. Essentially this machine is a prototype for a pickup winder I can use in instrument building workshops. I've learned a lot about the process of making pickups over the past few years, so know enough about it to be able to show others. By giving participants access to machine that are very simple to use, hopefully a lot of the head / heart aches I've experienced from wire snapping or whatever will be avoided.

6 Comments

1/13/2017 11:36:07 pm

wow nice interesting information and very helpful.

Reply

All around, this sort of winding machines has controlled for transformers.

Reply

A winding machine has included with metal wire, string or paper, onto an inside, spool, or bobbin, which are <a href="http://www.infantron.net/">automatic winding machine</a> unmistakable sorts of bowing machines from direct manual supervise machines to complex PC numeric control (CNC) machines.

Reply

Leave a Reply. |

AuthorMusician, experimental instrument designer, maker and educator. Info on current projects, dead ends, ideas. Archives

August 2015

Categories |

RSS Feed

RSS Feed